DURABILITY AND EFFICIENCY ARE MORE IMPORTANT THAN EVER!

This is the most challenging economy most of us have faced. There are fewer dollars available, so it’s time to take a look at how to save precious operating dollars:

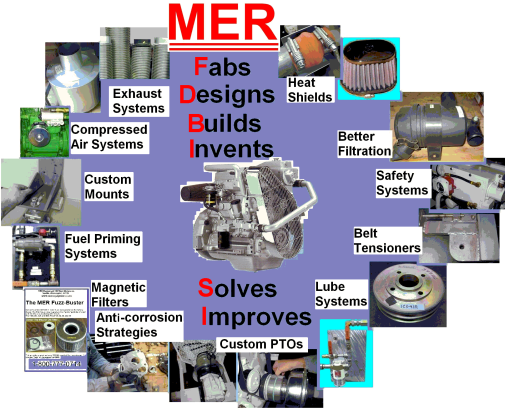

Follow along on the above illustration, starting at the top and working in a clockwise direction.

MER Heat Shields-Neither high tech or expensive, we add intake heat shields where needed, to minimize heat transfer into the intake air supply. Result: Better fuel efficiency.

Better Filtration-Our engines are equipped with either dual-element, or cleanable, low restriction air filters. Our new intake air silencer will make life on the boat much more comfortable. Result: Better fuel efficiency and lower maintenance cost.

Safety Systems-Our engines are so smart that they know when to sound an alarm, derate, or even stop to prevent engine damage. Result: Saves replacing your engine at half-life due, for example, to a failed coolant hose.

Belt Tensioners-Our belt tensioners keep the alternator, coolant pump and accessories turning like they should. Result: Saves replacing a good alternator due to belt slippage.

Lube Systems-Our engine pre-lube pump fully lubricates the engine (or transmission) before you start it up. This saves engines wear. Our system is valved to to also pump out old engine oil at oil change time. Result: Engines last longer and are easier to maintain. You will never have to worry again about whether or not the crew tightened the drain plug!

Custom PTOs-Our pto drives provide powerful and flexible options for running your accessories. Auxilliary drives off the engine are also available. Result: No vibration or clutch slippage, just trouble-free and productive time on the water.

Anti-Corrosion Strategies-Deere Extended Life Coolant, and Pen Ray Need-Release coolant conditioners stop electrical activity in the engine cooling system. Result: Your engine will last longer.

Marine LED Lighting-We are finding that our new LED marine lights require only one eighth the power of conventional sodium ar quartz lights. If you use lights for night fishing, our LEDs will put more light in the water and require less power doing it.

Magnetic Filters-Our Fuzz-Buster transmission filters grab and hold the small metal paticles that wear-out your transmission. Result: Longer and more dependable transmission life.

Fuel Priming Systems-The MER Diesel Prime system makes fuel filter changes and start-up easier and faster. Result: No more “grinding” on the starter motor to prime the fuel system.

Custom Engine, Transmission, and Generator Mounts-Our mount kits enable you to mount any equipment in a secure, vibration-free manner. Results: Provides for easy alignment and very quiet operation.

Compressed Air Systems-Our direct coupled engine-driven compressors supply large amounts of compressed air at a pressure of 120 psi. The compressors are “drive-thru”, meaning that additional accessories can be driven off the back of the air compressor. Result: No noisy electric air compressor on-board.

Exhaust Systems-Cowl and EM exhaust silencers, when coupled to high quality flex assemblies, provide quiet performance that lasts. Result: Lower over all maintenance cost.

MER Produces Problem Solvers!

24 08 2009Comments : Leave a Comment »

Tags: anti-corrosion strategies, better filtration, compressed air systems, custom belt tensioners, custom mounts, custom pto, engine intake air silencers, engine pre-lubers, engine safety systems, exhaust systems, fuel priming systems, heat shields, LED deck lights, light emitting diode, magnetic filters, marine LED lighting, night fishing lights

Categories : MER News Bulletin

MER Mounts Save Time and Dollars!

14 08 2009Call Gary, Norm, or Brian at 800-777-0714 To Order Yours

Weld-up mounting feet are available from MER to

make engine, transmission, and generator mounting

much faster and easier.

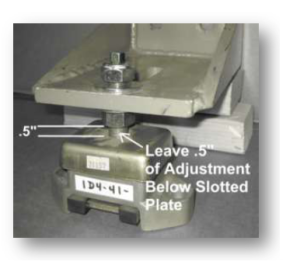

The finished product, seen below, works with your

existing mount holes on the engine block or

transmission, to properly place the slotted plate, and

provide a place for the adjustable mount to fit beneath.

To get to this point, suspend your engine,

transmission, or generator from a hoist or block it safely in the position needed.

Next lay out the MER pieces as shown, and be sure to leave .5″ of threads below the slotted plate, to allow for later adjustment of the mount itself. Tack weld them, and do a careful trial fit, making any needed adjustments before the final welding.

Comments : Leave a Comment »

Tags: custom mounts, engine alignment, engine feet, engine mounts, transmission alignment, vibration

Categories : Mechanical "How-To"

Recent Comments